In the field of powder coating, the

Electrostatic Powder Spray Machine serves as a vital device that brings a revolutionary change to the coating process. Let's delve into every aspect of this remarkable equipment.

An

Electrostatic Powder Spray Machine is a specialized apparatus designed to apply powder coatings with the assistance of electrostatic forces. It mainly comprises a powder - feeding system, a spray gun, an electrostatic generator, and a control panel.

The powder - feeding system stores and supplies the powder to the spray gun. It can be gravity - fed, where the powder drops due to gravity, or pressure - fed, with compressed air being used to propel the powder. The spray gun is where the key action occurs. It sprays the powder onto the workpiece. The electrostatic generator imparts a high - voltage charge to the powder as it passes through the gun. This charged powder is then attracted to the grounded workpiece, ensuring an even and efficient coating. The control panel enables the operator to adjust parameters such as powder - flow rate, electrostatic voltage, and air pressure.

These machines are widely utilized in multiple industries. In the automotive industry, they are employed to coat car bodies, engine components, and wheels. The electrostatic powder coating offers excellent corrosion resistance and a smooth finish. In the furniture manufacturing sector, metal furniture frames and parts are coated to enhance their durability and aesthetics. In the construction industry, metal building components like window frames, handrails, and roofing sheets are coated using electrostatic powder spray machines.

The price of an

Electrostatic Powder Spray Machine varies considerably. A basic, entry - level machine suitable for small - scale workshops or hobbyists can cost approximately $500 - $1500. These machines usually have simple functions and a basic powder - feeding system. Mid - range machines, featuring adjustable powder - flow control, better electrostatic performance, and a more durable construction, typically cost between $2000 - $5000. High - end industrial - grade machines, equipped with advanced features such as high - precision powder - metering systems, automated powder - reclaim, and intelligent control panels, can cost over $10000.

Before using the machine, ensure proper grounding to prevent electrical accidents. Connect all components correctly in accordance with the manufacturer's instructions. Prime the powder - feeding system with the appropriate powder. Adjust the powder - flow rate according to the size and shape of the workpiece. Set the electrostatic voltage based on the type of powder and the desired coating thickness. When spraying, hold the gun perpendicular to the workpiece and move it at a consistent speed. Maintain a distance of around 15 - 20 cm between the gun and the workpiece for optimal results.

When choosing an

Electrostatic Powder Spray Machine, take your production volume into consideration. For high - volume production, an industrial - grade machine with advanced features is essential. For small - scale production or hobbyist use, a basic or mid - range machine will be adequate. Also, consider the types of materials you'll be coating. Different materials may require different electrostatic settings and powder - flow rates. Your budget is another crucial factor. Balance your requirements with the cost to find the most suitable machine.

Safety is of utmost significance when using an

Electrostatic Powder Spray Machine. Wear appropriate personal protective equipment (PPE), including a dust mask to prevent inhalation of powder particles, safety goggles to protect your eyes, and gloves to protect your hands. Work in a well - ventilated area to avoid the accumulation of powder in the air, which can pose a fire or explosion hazard. Do not touch the electrostatic parts of the machine when it is in operation.

The design of an

Electrostatic Powder Spray Machine is highly rational. The electrostatic charging mechanism ensures efficient powder adhesion, reducing powder waste. The adjustable powder - flow and spray - pattern settings allow for customization according to different workpiece shapes and sizes. The use of high - quality materials in the construction of the machine ensures its long - term reliability and performance.

Q: What should I do if the powder coating has an uneven thickness?

A: Check the powder - flow rate and the electrostatic charge settings. An inconsistent powder - flow rate or incorrect electrostatic charge can cause uneven coating. Also, ensure the gun movement is steady and at the right speed.

Q: Can I use the machine for different types of powder?

A: Yes, but make sure to clean the powder - feeding system thoroughly between different powder types. Different powders may have different particle sizes and chemical compositions, which can affect the coating quality.

Q: How often should I maintain the electrostatic generator?

A: Conduct a monthly inspection of the electrostatic generator. Check for any loose connections or signs of wear. Do a comprehensive maintenance every 6 - 12 months, including cleaning and replacing worn - out parts.

Q: What if the powder doesn't spray out smoothly?

A: Check the powder - feeding system for any clogs. Also, make sure the air pressure (if it's an air - assisted system) is stable. Clean or replace the gun nozzle if it's dirty or damaged.

Q: Can I upgrade my existing electrostatic powder spray machine?

A: In some cases, yes. You can upgrade components like the powder - feeding system, the electrostatic generator, or the control panel. However, make sure the new components are compatible with your existing machine.

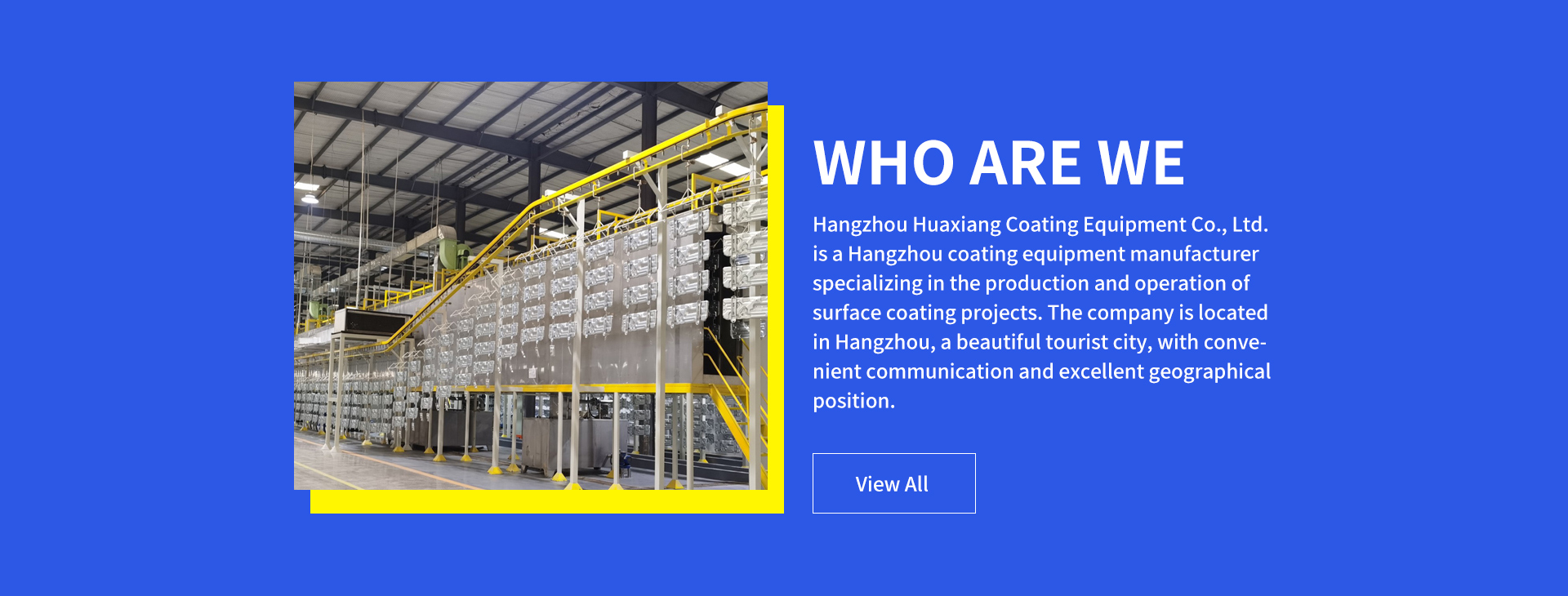

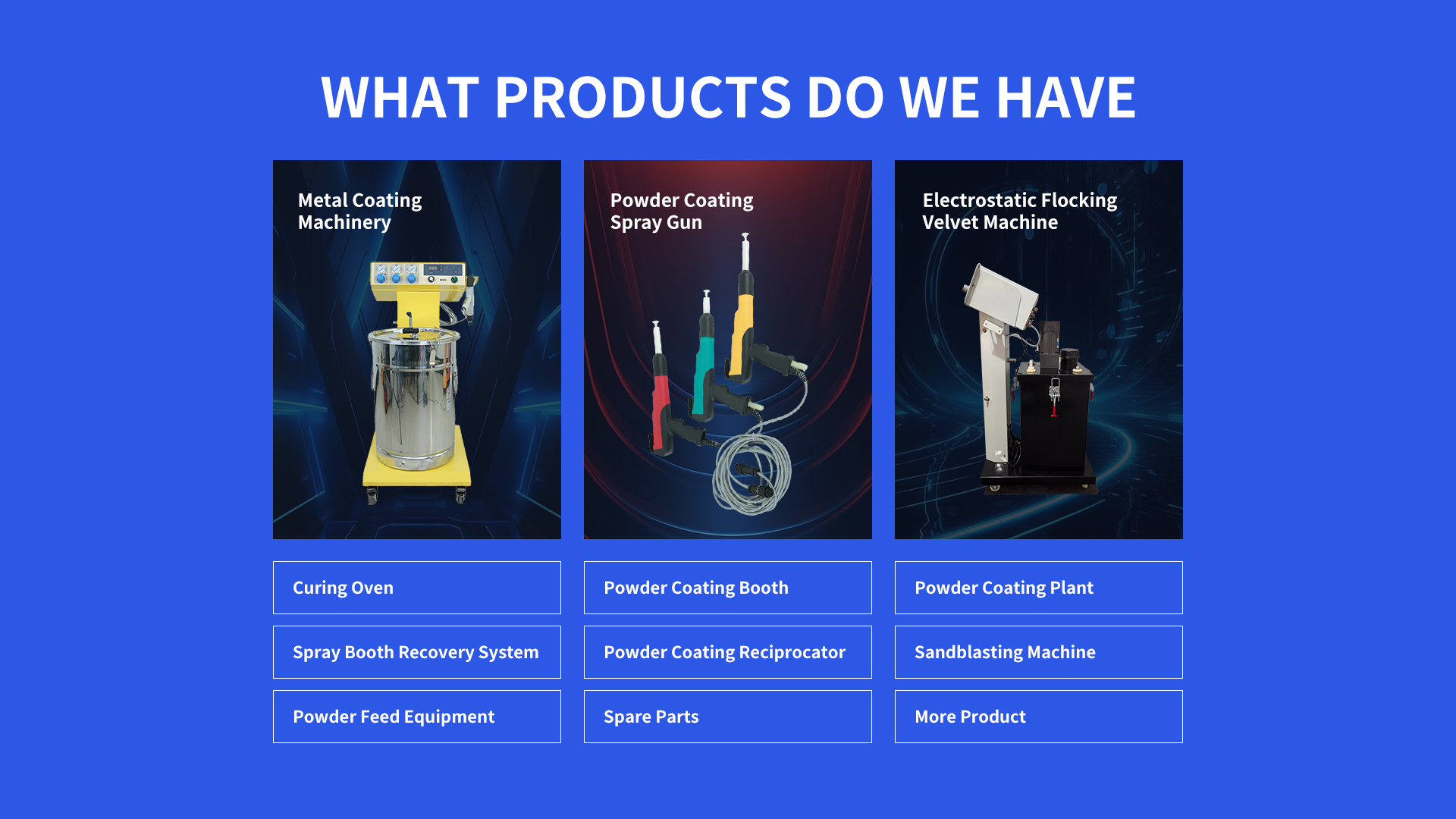

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com